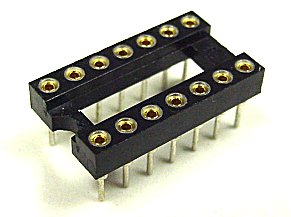

Figure 9. Machine tooled IC socket. Figure 9a. Contact removed from machined tooled socket.

This machine tooled IC socket (Fig.9) will be used for two different things. The individual sockets can be pressed out of the plastic base easily if you heat them with a soldering iron. (from the bottom side) Four of sockets will be used as quick connectors on the wires connecting to the actuators. Solder them to the wires, and then cover them with shrink wrap. Four more sockets will be cut apart to get the contacts (Fig.9a) from inside. The contacts are press fitted into the hollow sockets. The easiest way to remove them is to file the side of the socket until the contact is just exposed. A bit of prying should release it easily.