Introduction

With DC layouts short circuits were not much of a problem, but with the advent of DCC the power supplies now put out 5-8 amps, which if not controlled can easily melt down track and rolling stock.

Background

DC power packs are designed to run one train at a time, so a short circuit only affects one train and the power supplies are usually current limited to a safe value. DCC power packs (boosters) are designed to run many trains, and those used on larger layouts may have 5 or even 8 amp outputs. One solution to this problem is to invest in numbers of expensive electronic circuit breakers. Another option popularized by Allan Gartner (http://www.wiringfordcc.com/track.htm#5-4%20Bulb) is to wire a automobile tail light in series with one track feeder. This works but has some serious drawbacks as we shall note below.

How It Works

When a filament lamp is off and cool the resistance is very low. When the same lamp is on and the filament is very hot, the resistance is much higher, and will limit the current to the track. The tail light bulb commonly suggested to use is the 1156 lamp. This lamp draws about 2.5 amps when hot.

Problems

The main problems with this solution are:

- Many boosters rated at 5 amps will trip out electronically before the lamp has time to light, and if the lamp does not light it serves no purpose. When using 8 amp boosters this is not usually a problem.

- If more than one lamp is lighted due to multiple shorts, then the booster is much more likely to shut down on the second short. Once it has shut down, both lamps cool down and the booster will NOT come out of short circuit mode even after one of the shorts has been cleared up.

- When the lamp is on, it is drawing 2.5 amps through whatever truck or other running gear has caused the short circuit. If the short gets ignored for more than a minute or so this can cause meltdown of plastic parts. (it has happened)

- Risk of fire. When a tail light lamp is on it puts out 25-30 watts. This is more than enough to cause burns and even start a fire if the lamp is touching flammable materials.

Advantages

The big advantage of using lamps for circuit protection is that they provide a reasonable cost way to prevent short circuits on one section of the layout from shutting down operations on other sections powered by the same booster. On single user layouts this is not a factor, but on multi-user layouts this can be a very important consideration.

The glowing lamp is a visual aid for locating the shorted section of the layout.

Modifications

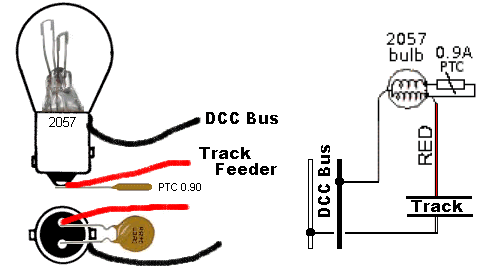

The key modification to make this idea work without the above problems is to use a common stop/tail lamp number 2057 and add a small component called a PTC fuse. The PTC fuse we chose is a 0.9A version. This will allow the full 2.1 amps of the stop filament, plus the 0.4 amps of the taillight filament, to flow for about 30-45 seconds before opening the circuit. Once the PTC unit opens the stop filament circuit, then only the 0.4 amp tail light element glows. This still provides an indication of the short circuit location, but drops the current to a safe value until the short is completely removed.

The Wiring

Simply solder the PTC fuse to the two lamp terminals, and connect the power leads, one to the tail light contact, and the other to the lamp shell.

The Parts

PTC Fuse

Littlefuse 30R090UU

Tyco/Raychem RUSBF090

Bourns MF-R090-0-9

2057 Auto lamp.